info@chemelot.nl

In line with Dutch and European ambitions, Chemelot will be a circular, sustainable and completely climate-neutral chemical site in 2050. It is very important that the basic chemical for the Netherlands is preserved, because this industry is the beginning of many economic value chains, such as plankton within many food chains. Fertilizers, clothing and medicines cannot exist without the raw materials that chemistry produces.

To continue fulfilling this vital role in a socially responsible manner, two challenges must be overcome:

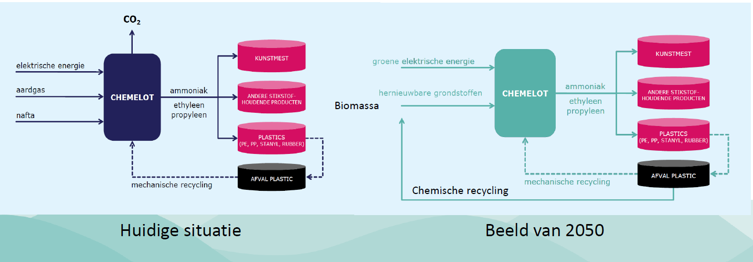

At the moment, many fossil raw materials are still used at Chemelot: roughly 4 million cubic meters of natural gas and approximately 93,000 barrels of naphtha ("refinery gasoline") per day. The electricity consumption is approximately 2 million megawatt hours per year.

Chemelot can be fully sustainable and circular by 2050. If there is one chemical site that can achieve sustainability, it is Chemelot. Chemelot is excellently positioned for its existing combination with the Brightlands Chemelot Campus, with institutes and research and upscaling facilities, and of course the Industrial Park with its residents.

To achieve this, a lot of work still needs to be done, and we are working hard on it. An example is the factory that SABIC and Plastic Energy will build on the Chemelot site. This factory, which will be operational in 2021, will chemically recycle plastic waste. Plastic Energy developed a special technology for this collaboration in which plastic waste is converted into so-called pyrolysis oil, which can then be used to make new plastic. Numerous projects are underway, such as AnQore, which produces Econitrile, the world's first sustainable and certified acrylonitrile. And by mid-2021, there will be a significant reduction in laughing gas emissions at Fibrant. With this, Fibrant reduces its nitrous oxide emission by more than 75% and makes a significant contribution to Chemelot's target of halving CO2 emissions by 2030. These are just a few examples.

Naphtha and natural gas will slowly but surely be replaced in this way by sustainable alternatives.Chemical processes need heat, which now often burns natural gas. High temperatures will continue to be required for the processes in the future, but this will be (sustainable) electric heat. For that reason, electricity consumption will roughly quadruple until 2050. Chemelot is not the problem within the climate discussion, but an indispensable link in the solution. On many fronts, Chemelot actively seeks cooperation with other companies and (knowledge) institutions and involved authorities to jointly realize these ambitions.

Chemelot's strategy fits seamlessly into the brand new Circular Hub Development Agenda. This Development Agenda has been drawn up in recent months by a broad alliance consisting of the municipality of Sittard-Geleen, the Province of Limburg, Chemelot Industriepark, Brightlands Chemelot campus, DSM, Brightsite, Brightlands Materials Center, AMI-BM, Maastricht University, Zuyd Hogeschool, Vista and CHILL.

With the focus on energy transition and boosting the circular economy, the parties have worked on a detailed project plan in the past six months to accelerate the transition to a circular economy and energy and raw materials transition, to strengthen the earning capacity of the Netherlands and the broad prosperity and improve well-being in Limburg.